Growth and Fabrication:

Characterization:

|

1. Physical properties measurement system 2. Magnetic properties measurement system 3. Hall measurement system 4. Closed-cycle cryostat 5. Probe station 6. Mini-SEM 7. Mini-XRD 8. Optical microscope |

Growth and Fabrication:

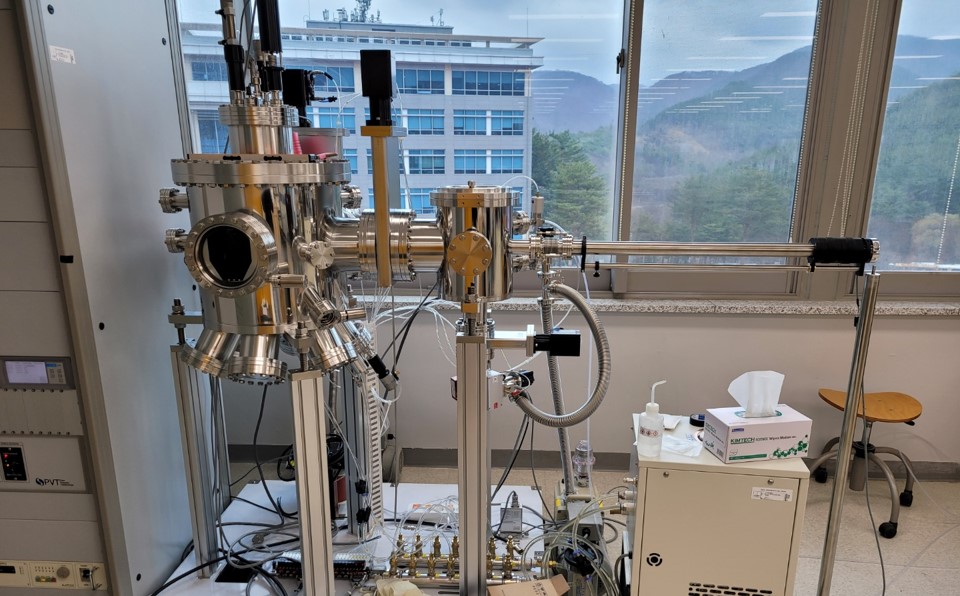

Specification:

1. Chamber : Main (< 5 x10^-9 Torr, up to 800 ºC, 6 gun ports), Loadlock (< 1 x10^-8 Torr)

2. Automatic pressure control unit

3. DC Power supply : Max 1000 W, CW CV CC control

Manual:

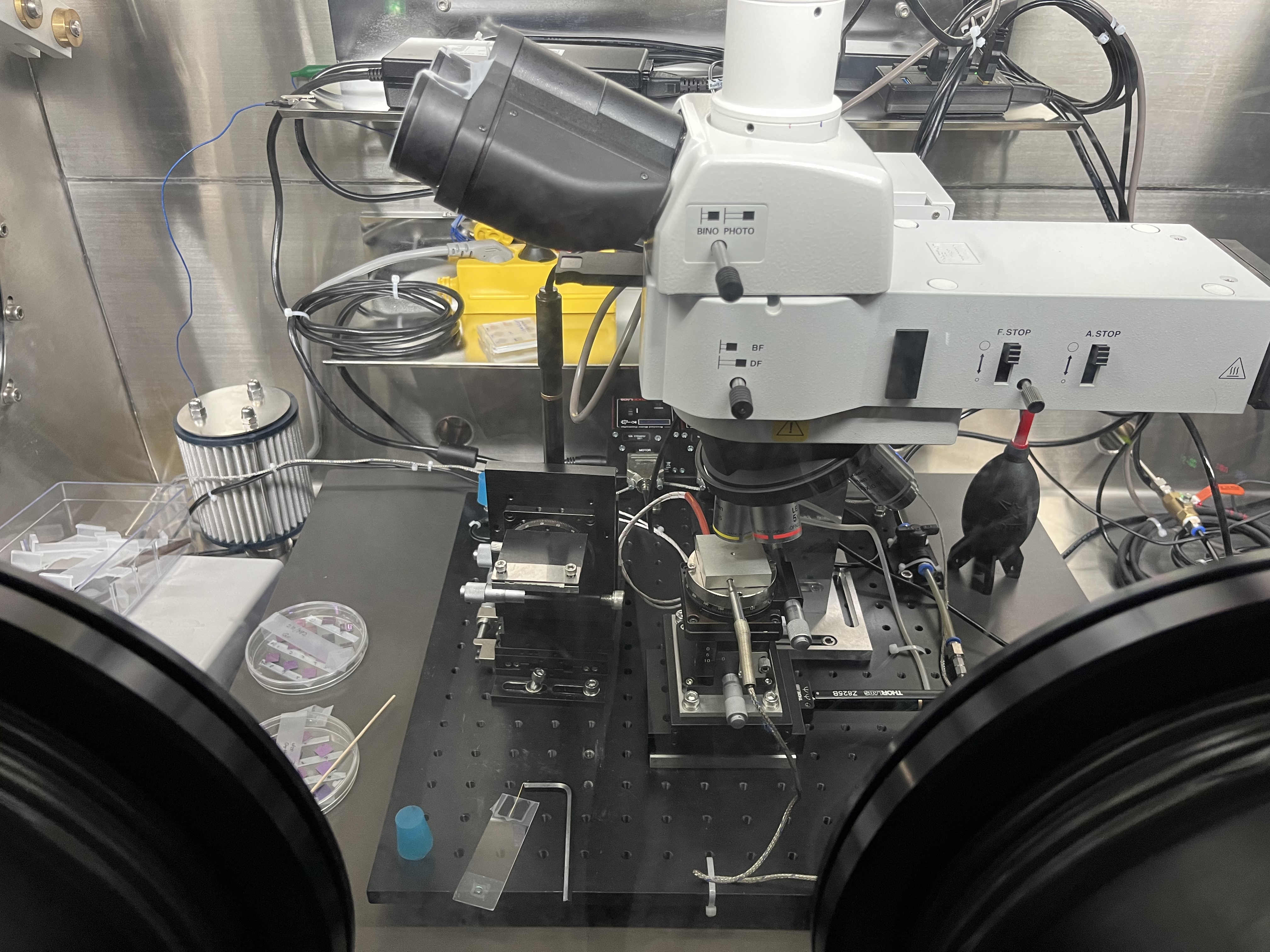

Specification:

1. Optical microscope (Nikon) : DS-Ri2 (Camera), Objective lens (5x, 10x, 20x, 50x, 100x), LED Lamphouse

2. XYZ stage : 8-axis manual & motorized linear stage, motorized linear stage

(resolution : 0.05 µm, range : 25 mm, 3-axis), heat up to 200 ºC

3. Active Vibration Isolation System (DVIA-T67, DAEIL SYSTEMS)

4. Conditions : O2, H2O < 1 ppm in Ar-filled glove box

Manual:

Atomic layer deposition: Tutorial, Animation

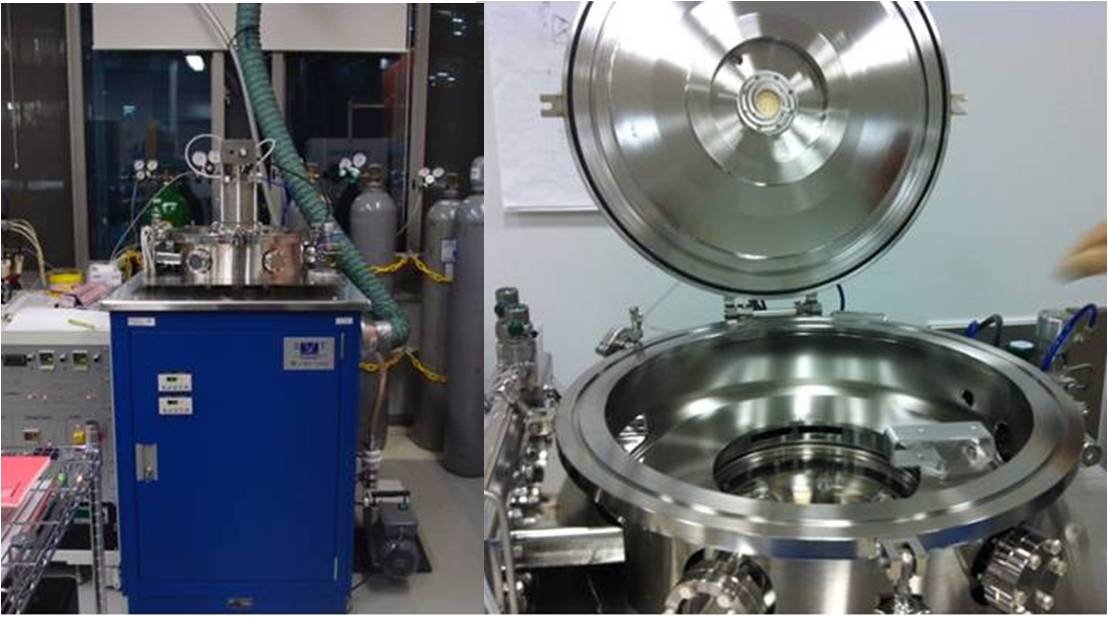

Specification:

1. Chamber: colsed coupled sample heater up to 500 C, QCM monitor

2. Gas delivery line: 2 carrier gas lines, 3. Precusor cells(2 with temperature control), plasma source line

4. Software control: Robo ALD process control

Manual:

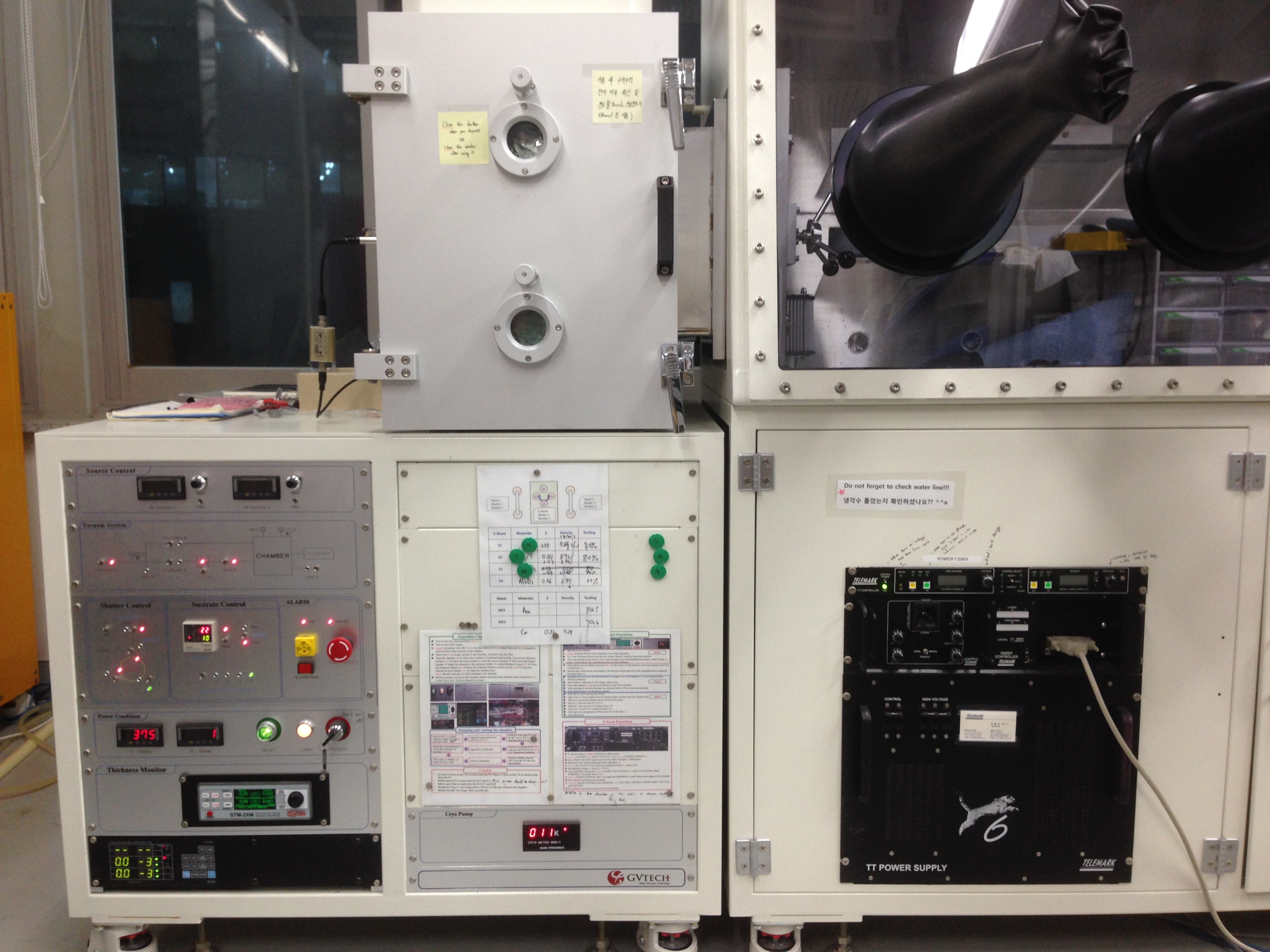

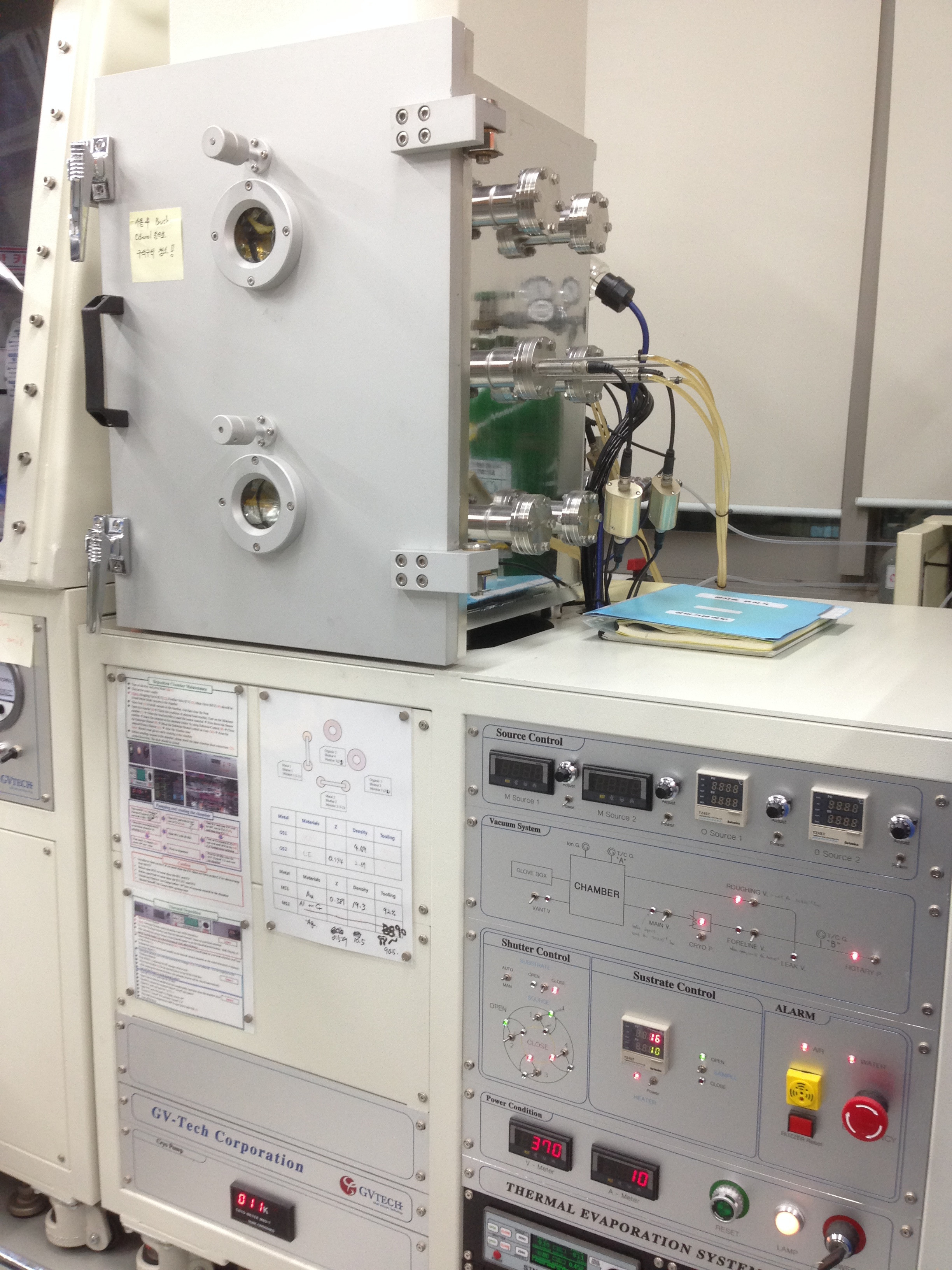

Specification:

2 thermal sources, 1 e-beam source (6kW, 7cc multi pocket), LN2 trap for substrate holder

Manual:

Specification:

3 temperature controllable organic source, 1 thermal sources, LN2 trap for substrate holder

Manual:

Specification:

1. Organic process chamber unit Features: 3 temperature controllable organic source, 1 metal sources, LN2 trap for substrate holder

2. Metal process chamber unit Features: 2 metal sources, 1 e-beam source (6kW, 7cc multi pocket)

3. 2 Glove box units with T-antichamber connection

Manual:

Specification:

1. Microwave power (2.45GHz, 50W/m2)

2. Gas: O2, Ar

3. Stage: 8 inch size

Specification:

Manual:

Specification:

1. Up to 6inch

2. UV lamp : Hg 350W

3. Wavelength : 350 ~ 450nm(I, H, G-line)

4. Lamp uniformity : ≤ 3%

3. Dual microscope(90X ~ 500X)

Manual:

Specification:

1. Etch Rate: 1000 - 3000 Å/min

2. Selectivity: ≤ 2±0.5:1 SiN:PR

3. Uniformity: ≤ ±3.0 %

4. RF Power: 600W

5. Selectivity:SiO2:Resist = 3~5 : 1 (Resist dependent)

Manual:

Specification:

1.Theoretical beam size : 2.1 nm for 100 keV, 7 nA

2. Line width : ≤ 5 nm

3. Deflection : vector scan, 55 MHz

4. Address grid resolution : 1 nm, 1 mm main field

5. Beam voltage : 30 ~ 100 keV

6. Writing area : 195 mm x 195 mm

7. Substrate size : 5 ~ 200 mm

8. Automation : 10 chucks automatic loading

9. Repeatable : 20 nm over wafer

Manual:

Characterization:

Specification:

1. Temperature Range : 1.9 K - 400 K

- Cryogen-free cooling technology.

- Continuous low-temperature control

- Controlled temperature sweep mode)

- Temperature accuracy : ±0.5 %

- Temperature stability : 0.2 % for T ≤10 K, 0.02 % for T > 10K

2. Magnet & Uniformity

- Magnet range : ±9 T (90,000 Gauss)

- Field resolution : 0.3 Oe to 1 T: 3 Oe to 9 T

- Slew Rate : Up to 200 Oe/sec

3. Elecrical Transport Option (ETO)

- Current Source Specifications: Current Range (10 nA to 100 mA), Frequency Range (DC, and 0.1Hz to 200 Hz AC)

- Resistance Specifications: Absolute Accuracy (0.1% for R < 200 kOhms), Relative Sensitivity (±10 nOhms RMS)

- Resistivity Range: 4uOhms to ~10 MOhms in 4-wire mode, 1 MOhms to ~5 GOhms in 2-wire mode (typical)

4. Vibrating Sample Magnetometer

- Geometry: Magnetic field II vibration and first order gradiometer coils, Coil-set bore (6.3 mm)

- Sample holders provided:

Tube (inner diameter = 3.2 mm; outer diameter = 4.8 mm)

Paddle (diameter = 3.2 mm), coil-set baseline (9 mm)

- VSM measurement parameters:

VSM oscillation frequency (calibrate): 40 Hz

VSM oscillation amplitude(typical): range of 0.5 mm - 10 mm peak-peak (typically 4 mm peak-peak)

- Sensitivity using the above typical parameters

Sensitivity : 2X10-6 emu/tesla with 1sec. averaging (typical)

Largest measurable moment : ∼150 emu (40 Hz, 1 mm p-p)

- VSM oven upto 1000 K

5. Thermal Transport System

- Thermal Conductivity κ

- Seebeck coefficient S

- Thermoelectric figure of merit ZT

6. Heat Capacity

- Temperature Range : 1.9 K - 400 K

- Sample Size: 1 - 500 mg(20 mg, typ.)

- Heat Capacity Resolution: 10 nJ/K at 2 K

- Measurement Accuracy: < 5%, 2 - 300 K < 2%, typ.

7. External electronics

- Keithley 2636 Duel channel sourcemeter

- Keithley 2400 Sourcemeter

- Keithley 2182A Nanovoltmeter

- Keithley 6221 AC/DC current source

- SR830 Lock-in amplifier

- SR310 High voltage

- 9x9 Matrix system

- AFG31101 Arbitrary Function Generator

- F10A High voltage linear amplifier

Manual:

Specification:

1. Temperature Range : 1.9 K - 400 K

- Cryogen-free cooling technology.

- Continuous low-temperature control

- Controlled temperature sweep mode)

- Temperature accuracy : ±0.5 %

- Temperature stability : 0.2 % for T ≤10 K, 0.02 % for T > 10K

2. Magnet & Uniformity

- Magnet range : ±9 T (90,000 Gauss)

- Field resolution : 0.3 Oe to 1 T: 3 Oe to 9 T

- Slew Rate : Up to 200 Oe/sec

Manual:

Specification:

Manual:

Specification:

Manual:

Specification:

Manual: